Product Center

Heavy Equipment Air Filter Factories – SK-1061A Air filter elements replace KOBELCO SK55 KATO HD307/308 CASE CX55/CX58 – Qiangsheng

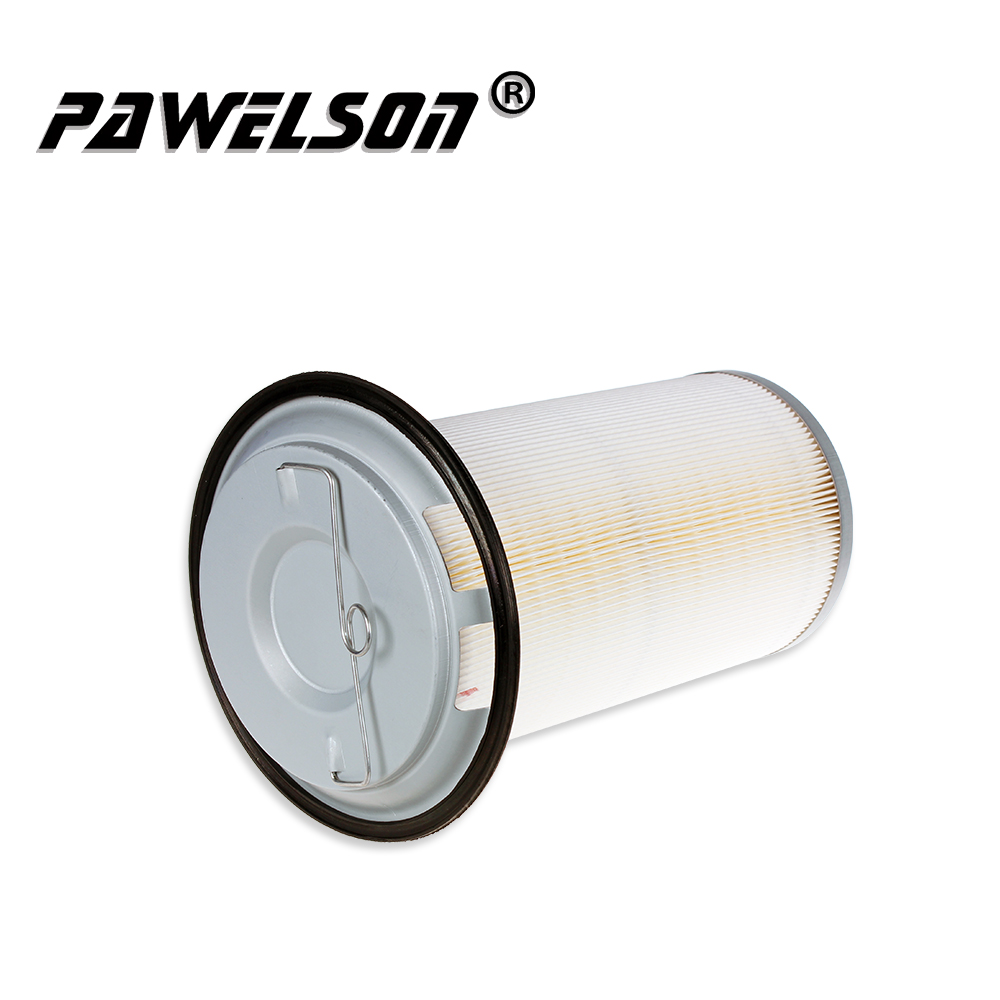

Heavy Equipment Air Filter Factories – SK-1061A Air filter elements replace KOBELCO SK55 KATO HD307/308 CASE CX55/CX58 – Qiangsheng Detail:

Features

(1) Suitable for the filtration of many kinds of dust in polishing, sand blasting and welding fumes , and powder dust collection.

(2) Spun bonded polyester with PTFE membrane, microspore Offers 99.99% filter efficiency.

(3) Wide pleat spacing and smooth, hydrophobic PTFE provides excellent particle release.

(4) Excellent resistance to chemical erosion.

(5) Electrical plate/stainless steel top and bottom, no rust Perforated zinc galvanized metal inner core allows good airflow.

Air Filter Elements

1.Using imported high quality materials, high precision, high dust holding capacity, good permeability, stable performance.Special filter paper embossing technology, fold uniformly, vertically and smoothly, more folds, more filter area increases.

2.With pioneered net lock technology, no burr, no rust; with thick net,so hardness is stronger, can effectively protect filter paper from Injury, and with grid smaller net, can effectively prevent particles to enter inside.

3.Using high-quality sealing tape, strong and flexible, not hard or bad;using AB glue, epoxy glue double paste, sealing performance enhanced.

4.Use high quality environmental friendly PU materials and molding technology, to ensure good end-elasticity, can against high pressure, and high or low temperature, seal firmly.

Importance of air filter

Everyone knows that the engine is the heart of a car, and the oil is the blood of the car. And do you know? There is also a very important part of the car, that is the air filter. The air filter is often overlooked by the drivers, but what everyone does not know is that it is such a small part that is very useful. The use of inferior air filters will increase your vehicle’s fuel consumption, cause the vehicle to produce serious sludge carbon deposits, destroy the air flow meter, severe throttle valve carbon deposits, and so on.We know that the combustion of gasoline or diesel in the engine cylinder requires inhalation of a large amount of air. There is a lot of dust in the air. The main component of dust is silicon dioxide (SiO2), which is a solid and insoluble solid, which is glass, ceramics, and crystals. The main component of the iron is harder than iron. If it enters the engine, it will aggravate the wear of the cylinder. In severe cases, it will burn engine oil, knock the cylinder and make abnormal noises, and eventually cause the engine to be overhauled. Therefore, in order to prevent these dust from entering the engine, an air filter is installed at the inlet of the engine’s intake pipe.

Application range

Water and oil filtration, petrochemical industry, oil field pipeline filtration;

Fuel filtration of refueling equipment and construction machinery and equipment;

Equipment filtration in water treatment industry;

Pharmaceutical and food processing fields;

Rotary vane vacuum pump oil filtration;

Maintenance

1. The filter element is the core component of the filter. It is made of special materials and is a vulnerable part that requires special maintenance and maintenance;

2. After the filter has been working for a long time, the filter element in it has blocked a certain amount of impurities, which will cause an increase in pressure and a decrease in flow rate. At this time, it needs to be cleaned in time;

3. When cleaning, be careful not to deform or damage the filter element.

Generally, depending on the raw materials used, the service life of the filter element is different, but with the extension of use time, impurities in the water will block the filter element, so generally the PP filter element needs to be replaced in three months; the activated carbon filter element needs to be replaced in six months ; As the fiber filter element cannot be cleaned, it is generally placed on the back end of PP cotton and activated carbon, which is not easy to cause clogging; the ceramic filter element can usually be used for 9-12 months.

How much do you know about air filters?

Air filter element is a type of filter, also known as air filter cartridge, air filter, style, etc. Mainly used for air filtration in engineering locomotives, automobiles, agricultural locomotives, laboratories, sterile operating rooms and various operating rooms.

Types of Air Filters

According to the filtration principle, the air filter can be divided into filter type, centrifugal type, oil bath type and compound type. The air filters commonly used in engines mainly include inertial oil bath air filters, paper dry air filters, and polyurethane filter element air filters.

The inertial oil bath air filter has undergone three-stage filtration: inertial filtration, oil bath filtration, and filter filtration. The latter two types of air filters are mainly filtered through the filter element. The inertial oil bath air filter has the advantages of small air intake resistance, can adapt to dusty and sandy working environment, and has a long service life.

However, this kind of air filter has low filtration efficiency, heavy weight, high cost and inconvenient maintenance, and has been gradually eliminated in automobile engines. The filter element of the paper dry air filter is made of resin-treated microporous filter paper. The filter paper is porous, loose, folded, has a certain mechanical strength and water resistance, and has the advantages of high filtration efficiency, simple structure, light weight and low cost. It has the advantages of low cost and convenient maintenance, etc. It is the most widely used air filter for automobiles at present.

Polyurethane filter element The filter element of the air filter is made of soft, porous, sponge-like polyurethane with strong adsorption capacity. This air filter has the advantages of a paper dry air filter, but has low mechanical strength and is used in car engines. more widely used. The disadvantage of the latter two air filters is that they have a shorter lifespan and are not reliable in working under harsh environmental conditions.

Product description

| QS NO. | SK-1061 |

| CROSS REFERENCE | KOBELCO SK55 |

| ENGINE | KATO HD307/308 |

| VEHICLE | CASE CX55/CX58 |

| LARGEST OD | 173(MM) |

| INTRNAL DIAMETER | 72(MM) |

| OVERALL HEIGHT | 247(MM) |

Our Workshop

Packing & Delivery

Our Exhibition

Our service

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Heavy Equipment Air Filter Factories – SK-1061A Air filter elements replace KOBELCO SK55 KATO HD307/308 CASE CX55/CX58 – Qiangsheng , The product will supply to all over the world, such as: Stuttgart, Greek, Japan, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.